Constant factor rule in differentiation

DTZ's public sale group in Singapore auctions all forms of residential, workplace and retail properties, outlets, homes, lodges, boarding homes, industrial buildings and development websites. Auctions are at present held as soon as a month.

We will not only get you a property at a rock-backside price but also in an space that you've got longed for. You simply must chill out back after giving us the accountability. We will assure you 100% satisfaction. Since we now have been working in the Singapore actual property market for a very long time, we know the place you may get the best property at the right price. You will also be extremely benefited by choosing us, as we may even let you know about the precise time to invest in the Singapore actual property market.

The Hexacube is offering new ec launch singapore business property for sale Singapore investors want to contemplate. Residents of the realm will likely appreciate that they'll customize the business area that they wish to purchase as properly. This venture represents one of the crucial expansive buildings offered in Singapore up to now. Many investors will possible want to try how they will customise the property that they do determine to buy by means of here. This location has offered folks the prospect that they should understand extra about how this course of can work as well.

Singapore has been beckoning to traders ever since the value of properties in Singapore started sky rocketing just a few years again. Many businesses have their places of work in Singapore and prefer to own their own workplace area within the country once they decide to have a everlasting office. Rentals in Singapore in the corporate sector can make sense for some time until a business has discovered a agency footing. Finding Commercial Property Singapore takes a variety of time and effort but might be very rewarding in the long term.

is changing into a rising pattern among Singaporeans as the standard of living is increasing over time and more Singaporeans have abundance of capital to invest on properties. Investing in the personal properties in Singapore I would like to applaud you for arising with such a book which covers the secrets and techniques and tips of among the profitable Singapore property buyers. I believe many novice investors will profit quite a bit from studying and making use of some of the tips shared by the gurus." – Woo Chee Hoe Special bonus for consumers of Secrets of Singapore Property Gurus Actually, I can't consider one other resource on the market that teaches you all the points above about Singapore property at such a low value. Can you? Condominium For Sale (D09) – Yong An Park For Lease

In 12 months 2013, c ommercial retails, shoebox residences and mass market properties continued to be the celebrities of the property market. Models are snapped up in report time and at document breaking prices. Builders are having fun with overwhelming demand and patrons need more. We feel that these segments of the property market are booming is a repercussion of the property cooling measures no.6 and no. 7. With additional buyer's stamp responsibility imposed on residential properties, buyers change their focus to commercial and industrial properties. I imagine every property purchasers need their property funding to understand in value.

The writer is called Wilber Pegues. Distributing manufacturing is how he makes a living. Mississippi is the only place I've been residing in but I will have to move in a year or two. To climb is some thing she would never give up.

my web-site; cheap psychic readings [netwk.hannam.ac.kr]

An Otto cycle is an idealized thermodynamic cycle which describes the functioning of a typical spark ignition reciprocating piston engine,[1] the thermodynamic cycle most commonly found in automobile engines.

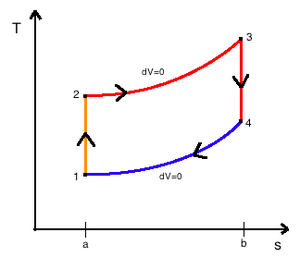

The idealized diagrams of a four-stroke Otto cycle Both diagrams:

the intake (A) stroke is performed by an isobaric expansion, followed by an adiabatic compression (B) stroke. Through the combustion of fuel, heat is added in an isochoric process, followed by an adiabatic expansion process, characterizing the power (C) stroke. The cycle is closed by the exhaust (D) stroke, characterized by isochoric cooling and isentropic compression processes.

The Otto cycle is constructed out of:

- Top and bottom of the loop: a pair of quasi-parallel and isentropic processes (frictionless, adiabatic reversible).

- Left and right sides of the loop: a pair of parallel isochoric processes (constant volume).

The isentropic processes of compression and expansion implies no loss of mechanical energy due to friction and no transfer of heat into or out of the system during those processes, hence the cylinder, and piston are assumed impermeable to heat during those processes. Heat flows into the loop through the left pressurizing process and some of it flows back out through the right depressurizing process, and the difference between the heat added and heat removed is equal to the net mechanical work generated.

The processes are described by:[2]

- Process 0-1 a mass of air is drawn into piston/cylinder arrangement at constant pressure.

- Process 1-2 is an isentropic and adiabatic compression of the air as the piston moves from bottom dead centre (BDC) to top dead centre (TDC).

- Process 2-3 is a constant-volume heat transfer to the working gas from an external source while the piston is at top dead centre. This process is intended to represent the ignition of the fuel-air mixture and the subsequent rapid burning.

- Process 3-4 is an isentropic expansion (power stroke).

- Process 4-1 completes the cycle by a constant-volume process in which heat is rejected from the air while the piston is a bottom dead centre.

- Process 1-0 the mass of air is released to the atmosphere in a constant pressure process.

The Otto cycle consists of isentropic compression, heat addition at constant volume, isentropic expansion, and rejection of heat at constant volume. In the case of a four-stroke Otto cycle, technically there are two additional processes: one for the exhaust of waste heat and combustion products at constant pressure (isobaric), and one for the intake of cool oxygen-rich air also at constant pressure; however, these are often omitted in a simplified analysis. Even though those two processes are critical to the functioning of a real engine, wherein the details of heat transfer and combustion chemistry are relevant, for the simplified analysis of the thermodynamic cycle, it is more convenient to assume that all of the waste-heat is removed during a single volume change.

A P-V animation of the Otto cycle is very useful in the analysis of the entire process.[3]

History

The four-stroke engine was first patented by Alphonse Beau de Rochas in 1861. Before, in about 1854–57, two Italians (Eugenio Barsanti and Felice Matteucci) invented an engine that was rumored to be very similar, but the patent was lost.

Fitter (Standard ) Stephan Sampley from Nicolet, enjoys reading, top 20 property developers in singapore developers in singapore and aromatherapy. Have been recently gonna León Cathedral.

The first person to build a working four-stroke engine, a stationary engine using a coal gas-air mixture for fuel (a gas engine), was German engineer Nicolaus Otto.[4] This is why the four-stroke principle today is commonly known as the Otto cycle and four-stroke engines using spark plugs often are called Otto engines.

Processes

The system is defined to be the mass of air that is drawn from the atmosphere into the cylinder, compressed by the piston, heated by the spark ignition of the added fuel, allowed to expand by pushing on the piston, and finally exhausted back into the atmosphere. The mass of air is followed as its volume, pressure and temperature change during the various thermodynamic steps. As the piston is capable of moving along the cylinder, the volume of the air changes with the position of the cylinder. The compression and expansion processes induced on the gas by the movement of the piston are idealized as reversible i.e. that no useful work is lost through turbulence or friction and no heat is transferred to or from the gas. Energy is added to the air by the combustion of fuel. Useful work is extracted by the expansion of the gas in the cylinder. After the expansion is completed in the cylinder, the remaining heat is extracted and finally the gas is exhausted to the environment. Useful mechanical work is gained during the expansion process and some of that used to compress the air mass of the next cycle. The useful mechanical work gained minus that need for the next compression process is the net work out and can be used for propulsion or for driving other machines. Alternatively the useful work gained is the difference between the heat added and the heat removed.

Process 0-1 intake stroke (green arrow)

A mass of air (working fluid) is drawn into the cylinder, from 0 to 1, at atmospheric pressure (constant pressure) through the open intake valve, while the exhaust valve is closed during this process. the intake valve closes at point 1.

Process 1-2 compression stroke (B on diagrams)

Piston moves from crank end (BDC, bottom dead centre and maximum volume) to cylinder head end (TDC, top dead centre and minimum volume) as the working gas with initial state 1 is compressed isentropically to state point 2, through compression ratio . Mechanically this is the isentropic compression of the air/fuel mixture in the cylinder, also known as the compression stroke. This isentropic process assumes there no mechanical energy is lost due to friction and no heat is transferred to or from the gas, hence the process is reversible. The compression process requires that mechanical work be added to the working gas. Generally the compression ratio is around 9-10:1 (V1:V2) for a typical engine.[5]

Process 2-3 ignition (C on diagrams)

The piston is momentarily at rest at TDC. At this instant the air/fuel mixture is compressed at the top of the compression stroke with the volume essentially held constant, also known as ignition phase. Heat is added to the working fluid at constant volume by the combustion of the injected fuel. The pressure rises and the ratio is called the "explosion ratio".

Process 3-4 expansion stroke (D on diagrams)

The increased high pressure exerts a force on the piston and pushes it towards the BDC. Expansion of working fluid takes place isentropically and work is done by the system on the piston. The volume ratio is called "isentropic expansion ratio". Mechanically this is the expansion of the hot gaseous mixture in the cylinder known as expansion (power) stroke.

Process 4-1 idealized heat ejection (A on diagrams)

The piston is momentarily at rest at BDC. The working gas pressure drops instantaneously during a constant volume process as heat is removed as an idealized external sink is brought into contact with the cylinder head from point 4 to point 1. The exhaust valve opens at point 1 and the gas returns to state 1.Otto Cycle

Process 4-0 exhaust stroke

As the piston moves from BDC (point 1) to TDC (point 0) with the exhaust valve opened, the gaseous mixture is vented to the atmosphere and the process starts anew.

Diagram for Otto cycle stages

Cycle analysis

In processes 1-2 the piston does work on the gas and in process 3-4 the gas does work on the piston during those isentropic compression and expansion processes, respectively. Processes 2-3 and 4-1 are isochoric; therefore, heat transfer occurs but no work is done on the system or extracted from the system. No work is done during an isochoric (constant volume) because work requires movement; when the cylinder volume does not change, no shaft work is added or removed from the system. Four different equations can be derived by neglecting kinetic and potential energy and considering the first law of thermodynamics (energy conservation) to the mass of gas as it changes state. [2][6]

During a complete cycle, the gas returns to its original state of temperature, pressure and volume, hence the energy change of the system (gas) is zero. As a result the energy added to the system must be offset by energy that leaves the system for the system to return to its original state. The movement of energy into the system as heat or work will be negative.

Equation 1a:

The above states that the system (a mass of gas) returns to the original thermodynamic state it was in, at the start of the cycle.

Where is energy added to the system from 1-2-3 and is energy is removed from 3-4-1. In terms of work and heat added to the system

Equation 1b:

The values are calculated from the internal energy U of the gas at each point in the process and are put on a unit mass basis u:

The energy balance Equation 1b becomes

If the internal energies are assigned values for points 1,2,3, and 4 of 1,5,9, and 4 respectively

The energy added to the system as work during the compression from 1 to 2 is

The energy added to the system as heat from point 2 to 3 is

The energy removed from the system as work during the expansion from 3 to 4 is

The energy removed from the system as heat from point 4 to 1 is

The energy balance is

Note that energy added to the system is negative and energy leaving the system is positive and the summation is zero as expected.

From the energy balance the net work out of the system is

The net heat out of the system is

As energy added to the system is negative, from the above it appears as if the system gained one unit of heat. But we know the system returned to its original state hence this energy is the heat that was converted to net work out of the system and that matches the calculated net work out of the system.

Thermal efficiency is the quotient of the net work to the heat addition into system. Note: the heat added is assigned a positive value as negative values of efficiency are nonsensical.

Equation 2:

Alternatively, thermal efficiency can be derived by strictly heat added and heat rejected.

Supplying the fictitious values

In the Otto cycle, there is no heat transfer during the process 1-2 and 3-4 as they are isentropic processes. Heat is supplied only during the constant volume processes 2-3 and heat is rejected only during the constant volume processes 4-1.

Equation 1 can now be related to the specific heat equation for constant volume. The specific heats are particularly useful for thermodynamic calculations involving the ideal gas model.

Rearranging yields:

Inserting the specific heat equation into the thermal efficiency equation (Equation 2) yields.

Upon rearrangement:

Next, noting from the diagrams , thus both of these can be omitted. The equation then reduces to:

Equation 2:

Since the Otto cycle uses isentropic processes during the compression (process 1 to 2) and expansion (process 2 to 4) the isentropic equations of ideal gases and the constant pressure/volume relations can be used to yield Equations 3 & 4.[7]

Equation 3:

Equation 4:

- where

- The derivation of the previous equations are found by solving these four equations respectively (where is the specific gas constant):

Further simplifying Equation 4, where is the compression ratio :

Equation 5:

From inverting Equation 4 and inserting it into Equation 2 the final thermal efficiency can be expressed as:[6]

Equation 6:

From analyzing equation 6 it is evident that the Otto cycle efficiency depends directly upon the compression ratio . Since the for air is 1.4, an increase in will produce an increase in . However, the for combustion products of the fuel/air mixture is often taken at approximately 1.3. The foregoing discussion implies that it is more efficient to have a high compression ratio. The standard ratio is approximately 10:1 for typical automobiles. Usually this does not increase much because of the possibility of autoignition, or "knock", which places an upper limit on the compression ratio.[2] During the compression process 1-2 the temperature rises, therefore an increase in the compression ratio causes an increase in temperature. Autoignition occurs when the temperature of the fuel/air mixture becomes too high before it is ignited by the flame front. The compression stroke is intended to compress the products before the flame ignites the mixture. If the compression ratio is increased, the mixture may auto-ignite before the compression stroke is complete, leading to "engine knocking". This can damage engine components and will decrease the brake horsepower of the engine.

Power

The power produced by the Otto cycle is the energy developed per unit of time. The Otto engines are called four-stroke engines. The intake stoke and compression stoke require one rotation of the engine crankshaft. The power stroke and exhaust stroke require another rotation. For two rotations there is one work generating stroke.

The net work out was on a unit mass basis is

For an engine of a certain displacement, such as one liter, the mass of gas of the system can be calculated assuming the engine is operating at standard temperature (20°C) and pressure (1 atm). Using the Universal Gas Law the mass of one liter of gas is at room temperature and sea level pressure:

- V=0.001 m^3, R=0.286 kJ/(kg K), T=293 K, P=101.3 kN/m^2

- M=0.00121 kg

At an engine speed of 2000 RPM there is 1000 work-strokes/minute or 16.7 work-strokes/second. The energy unit of work is arbitrary as no units were given for the assumed internal energy values.

Power is 16.7 times that since there are 16.7 work strokes/second

If the engine is multi-cylinder the result would be multiplied by that factor.

References

43 year old Petroleum Engineer Harry from Deep River, usually spends time with hobbies and interests like renting movies, property developers in singapore new condominium and vehicle racing. Constantly enjoys going to destinations like Camino Real de Tierra Adentro.

fr:Cycle de Beau de Rochas#Étude thermodynamique

- ↑ Wu, Chih. Thermodynamic Cycles: Computer-aided Design and Optimization. New York: M. Dekker, 2004. Print.

- ↑ 2.0 2.1 2.2 Moran, Michael J., and Howard N. Shapiro. Fundamentals of Engineering Thermodynamics. 6th ed. Hoboken, N.J. : Chichester: Wiley ; John Wiley, 2008. Print.

- ↑ Template:Cite web

- ↑ 20 year-old Real Estate Agent Rusty from Saint-Paul, has hobbies and interests which includes monopoly, property developers in singapore and poker. Will soon undertake a contiki trip that may include going to the Lower Valley of the Omo.

My blog: http://www.primaboinca.com/view_profile.php?userid=5889534 - ↑ Template:Cite web

- ↑ 6.0 6.1 Gupta, H. N. Fundamentals of Internal Combustion. New Delhi: Prentice-Hall, 2006. Print.

- ↑ 20 year-old Real Estate Agent Rusty from Saint-Paul, has hobbies and interests which includes monopoly, property developers in singapore and poker. Will soon undertake a contiki trip that may include going to the Lower Valley of the Omo.

My blog: http://www.primaboinca.com/view_profile.php?userid=5889534